Solar power is not only the fastest growing energy technology in recent history but also one of the cheapest energy sources and the most impactful in terms of reducing greenhouse gas emissions.

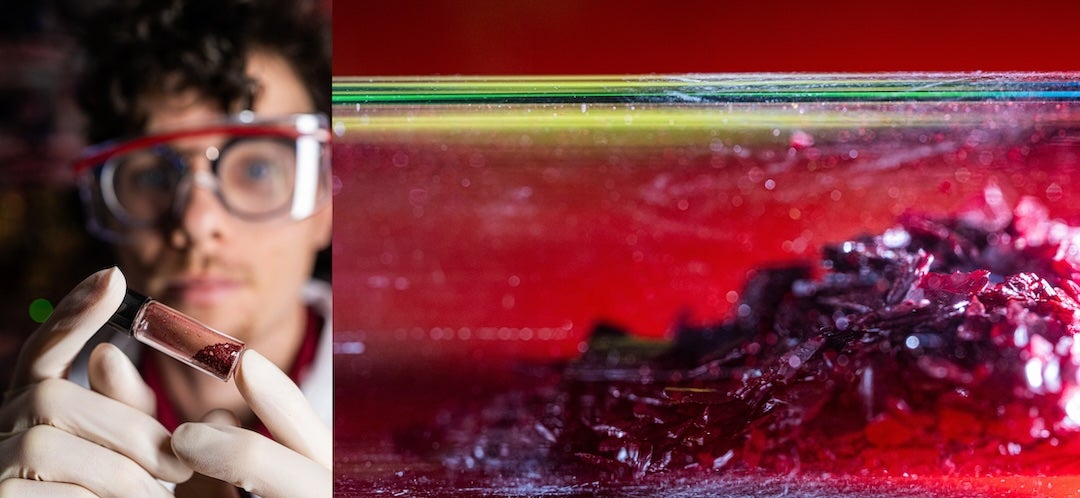

A Rice University study featured on the cover of today’s issue of Science describes a way to synthesize formamidinium lead iodide (FAPbI3) ⎯ the type of crystal currently used to make the highest-efficiency perovskite solar cells ⎯ into ultrastable, high-quality photovoltaic films. The overall efficiency of the resulting FAPbI3 solar cells decreased by less than 3% over more than 1,000 hours of operation at temperatures of 85 degrees Celsius (185 Fahrenheit).

“Right now, we think that this is state of the art in terms of stability,” said Rice engineer Aditya Mohite, whose lab has achieved progressive improvements in the perovskites’ durability and performance over the past several years. “Perovskite solar cells have the potential to revolutionize energy production, but achieving long-duration stability has been a significant challenge.”

With this most recent breakthrough, Mohite and collaborators have reached a critical milestone toward making perovskite photovoltaics market-ready. The key was “seasoning” the FAPbI3 precursor solution with a sprinkling of specially designed two-dimensional (2D) perovskites. These served as a template guiding the growth of the bulk/3D perovskite, providing added compression and stability to the crystal lattice structure.

“Perovskite crystals get broken in two ways: chemically ⎯ destroying the molecules that make up the crystal ⎯ and structurally ⎯ reordering the molecules to form a different crystal,” said Isaac Metcalf, a Rice materials science and nanoengineering graduate student and a lead author on the study. “Of the various crystals that we use in solar cells, the most chemically stable are also the least structurally stable and vice versa. FAPbI3 is on the structurally unstable end of that spectrum.”

While more stable than FAPbI3 both chemically and structurally, 2D perovskites are typically not great at harvesting light, making them a poor choice of material for solar cells. However, the researchers hypothesized that 2D perovskites used as templates for growing FAPbI3 films might impart their stability to the latter. To test this idea, they developed four different types of 2D perovskites ⎯ two with a surface structure nearly indistinguishable from that of FAPbI3 and two less well-matched ⎯ and used them to make different FAPbI3 film formulations.

“The addition of well-matched 2D crystals made it easier for FAPbI3 crystals to form, while poorly matched 2D crystals actually made it harder to form, validating our hypothesis,” Metcalf said. “FAPbI3 films templated with 2D crystals were higher quality, showing less internal disorder and exhibiting a stronger response to illumination, which translated as higher efficiency.”

The 2D crystal templates improved not only the efficiency of FAPbI3 solar cells but also their durability. While solar cells without any 2D crystals degraded significantly after two days of generating electricity from sunlight in air, solar cells with 2D templates did not start degrading even after 20 days. By adding an encapsulation layer to the 2D-templated solar cells, stability was further improved to timescales approaching commercial relevance.

These findings could have a transformative impact on light-harvesting, or photovoltaic, technologies, further reducing manufacturing costs and enabling the construction of solar panels with a simplified structure that are lighter weight and more flexible than their silicon-based counterparts.

“Perovskites are soluble in solution, so you can take an ink of a perovskite precursor and spread it across a piece of glass, then heat it up and you have the absorber layer for a solar cell,” Metcalf said. “Since you don’t need very high temperatures ⎯ perovskite films can be processed at temperatures below 150 Celsius (302 Fahrenheit) ⎯ in theory that also means perovskite solar panels can be made on plastic or even flexible substrates, which could further reduce costs.”

Although it is the most widely used semiconductor in photovoltaic cells, silicon entails manufacturing processes that are more resource-intensive than those of emerging alternatives. Among these, halide perovskites stand out for their soaring efficiencies, which have gone from 3.9% in 2009 to over 26% currently.

“It should be much cheaper and less energy-intensive to make high-quality perovskite solar panels compared to high-quality silicon panels, because the processing is so much easier,” Metcalf said.

“We need to urgently transition our global energy system to an emissions-free alternative,” he added, pointing to United Nations’ Intergovernmental Panel on Climate Change estimates that “make a strong case for solar as an alternative to fossil fuels.”

Mohite underscored that advancements in solar energy technologies and infrastructure are critical for achieving the greenhouse gas emissions 2030 target and preventing a 1.5 degrees Celsius rise in global temperatures, which “would then set us on the right course to achieve net zero carbon emissions by 2050.”

“If solar electricity doesn’t happen, none of the other processes that rely on green electrons from the grid, such as thermochemical or electrochemical processes for chemical manufacturing, will happen,” Mohite said. “Photovoltaics are absolutely critical.”

Mohite is Rice’s William M. Rice Trustee Professor, a professor of chemical and biomolecular engineering, and faculty director of the Rice Engineering Initiative for Energy Transition and Sustainability. In addition to Metcalf, Siraj Sidhik, a Rice doctoral alumnus, is a lead author on the study.

“I would like to give a lot of credit to Siraj, who started this project based on a theoretical idea by Professor Jacky Even at the University of Rennes,” Mohite said. “I would also like to thank our collaborators at the national labs and at several universities in the U.S. and abroad whose help was instrumental to this work.”

Additional co-authors include researchers from several institutions in the U.S. and abroad, including Lawrence Berkeley National Laboratory; University of California, San Diego; University of Lille, National Center for Scientific Research (CNRS), Centrale Lille Institut; University of Artois; Northwestern University; Purdue University; University of Rennes, INSA Rennes, CNRS, Institut FOTON; Brookhaven National Laboratory; University of Washington; and Northwestern University.

The research was supported by the U.S. Department of Energy (EE0010738, AC02-05CH11231), the Hertz Foundation, the National Science Foundation (20587), the Air Force Research Laboratory, the Office of Naval Research (N00014-20-1-2587), the Army Research Office, the China Scholarship Council (202107990007), the Institut Universitaire de France and the German Science Foundation (KO6414). The content in this press release is solely the responsibility of the authors and does not necessarily represent the official views of the funders.